Series: performance

Developed by professionals for professionals!

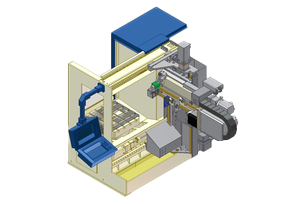

Developed by the mold maker, the practical requirements were incorporated 1:1 into the design. The machine frame is designed in a gantry design, which means it has extremely high rigidity under dynamic loads.

In combination with the know-how in mechanical engineering and deep drilling technology, an excellent product has been created for practical use.

The highlight of the BUCK drill machine concept, developed by a mold maker and perfected into a high-performance product. The gantry design stands for maximum rigidity, long-term precision and thermal stability with a small space requirement.

This leading design allows the machine to be set up without foundations. Equipped with the latest control and drive technology, the performance series enables highly effective and economical 4-sided deep drilling and milling. Equipped with automation technology, savings in non-productive time of more than 60% can be achieved and production time can be reduced by more than 30%.

Conclusion: Ideal for the use of medium and large, very complex components.

Practice-oriented development and therefore ideal for use in tool and mold making.

PERFORMANCE SERIES

MACHINE DESCRIPTION

- Patented machine technology

- Extremely high rigidity and best damping properties

- High precision and long-term accuracy thanks to the gantry guidance system

- Crane hook machine therefore no foundation required

- Deep hole drilling, drilling, countersinking, threading and milling without conversion

- Traveling 2/4-fold support bezels

- High-pressure coolant system up to 140 bar

- Extensive basic equipment (chip conveyor, etc.)